The MADE-PUBLIC (Manufacturing ADvanced Electronics through Printing Using Bio-based and Locally Identifiable Compounds) project is an interdisciplinary collaboration between materials scientists, engineers, and agronomists of multiple institutions. Our overarching goal is utilizing locally-grown plant material for low-cost 3D-printing of electronic devices. The demand for electronics will continue as societies become increasingly technological, so establishing renewable and sustainable methods of producing these products will be crucial for supporting our high-tech world.

Plants with high vegetative biomass yield can make great teammates for achieving this goal. The MADE-PUBLIC project is working with switchgrass, miscanthus, and industrial fiber hemp to explore their potential as cellulose and lignin feedstocks. Cellulose is composed of cellulose nanocrystals (CNC), which have a variety of applications in industry including pharmaceuticals, fabrics, energy storage methods, membranes, or even air filters! Lignin can be processed into graphene, which is useful in important products, for example, batteries. Our work in the Lee Lab is focusing on studying the potential of switchgrass, miscanthus, and hemp as our sources of CNC and lignin.

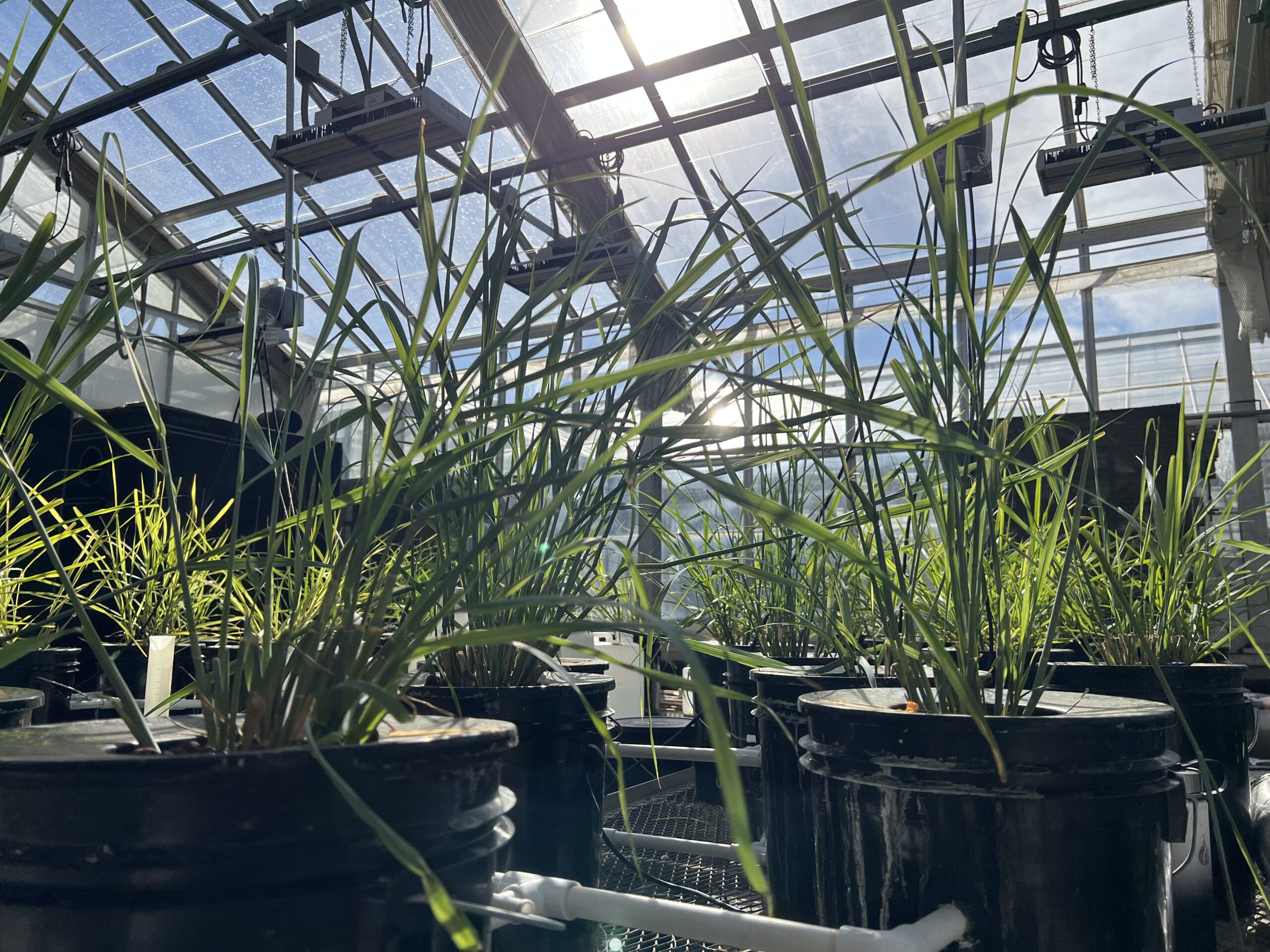

Greenhouse experiments are ongoing to test how different nutrient availabilities may affect the composition of fiber components in switchgrass, miscanthus, and hemp. Using an aeroponic system for precision fertilization, we can observe how nutrient recipes such as an excess of Nitrogen, or a deficiency of Potassium, could influence the accumulation of lignin or cellulose. Wet chemistry procedures to quantify the chemical composition of fiber is performed on biomass harvested from the aeroponic systems to understand if ratios of cellulose, hemicellulose, lignin, and ash responded to different fertilizer treatments. Additionally, microscopy in collaboration with the Institute of Genomic Biology (IGB) allows us to measure changes to cellular morphology in response to different nutritional environments.

These plants are provided specific nutrient recipes to observe if the fiber composition responds to different macronutrient availabilities. The tissue is also harvested for microscopy work to measure possible changes in cell wall morphology.

Aeroponic systems in the Greenhouse

Plants are provided with specific fertilizer recipes to test if fiber composition or cellular morphology responds to changes in macronutrient concentrations.

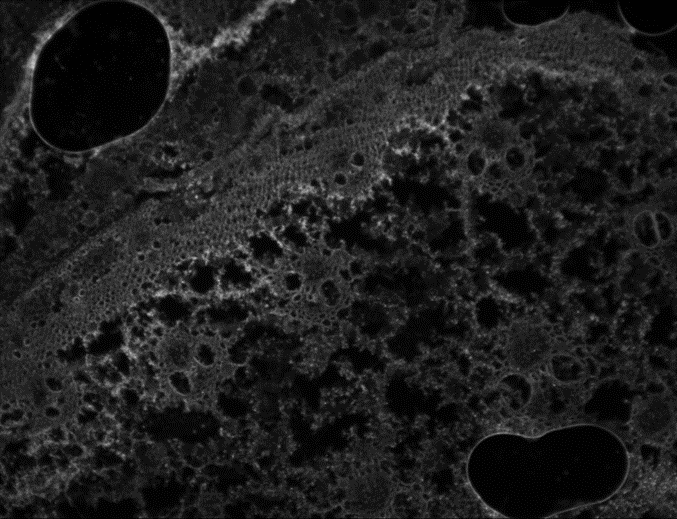

Cross-Section of Switchgrass Stem

20-micro-meters thick cross-section of switchgrass stem at 112x magnification on the AxioZoom V16 – Zeiss V16 Zoom Microscope. Tissue was stained with Calcofluor-White with KOH to make cellulose deposits in the cell walls fluorescent under CW2MR (432nm) light.

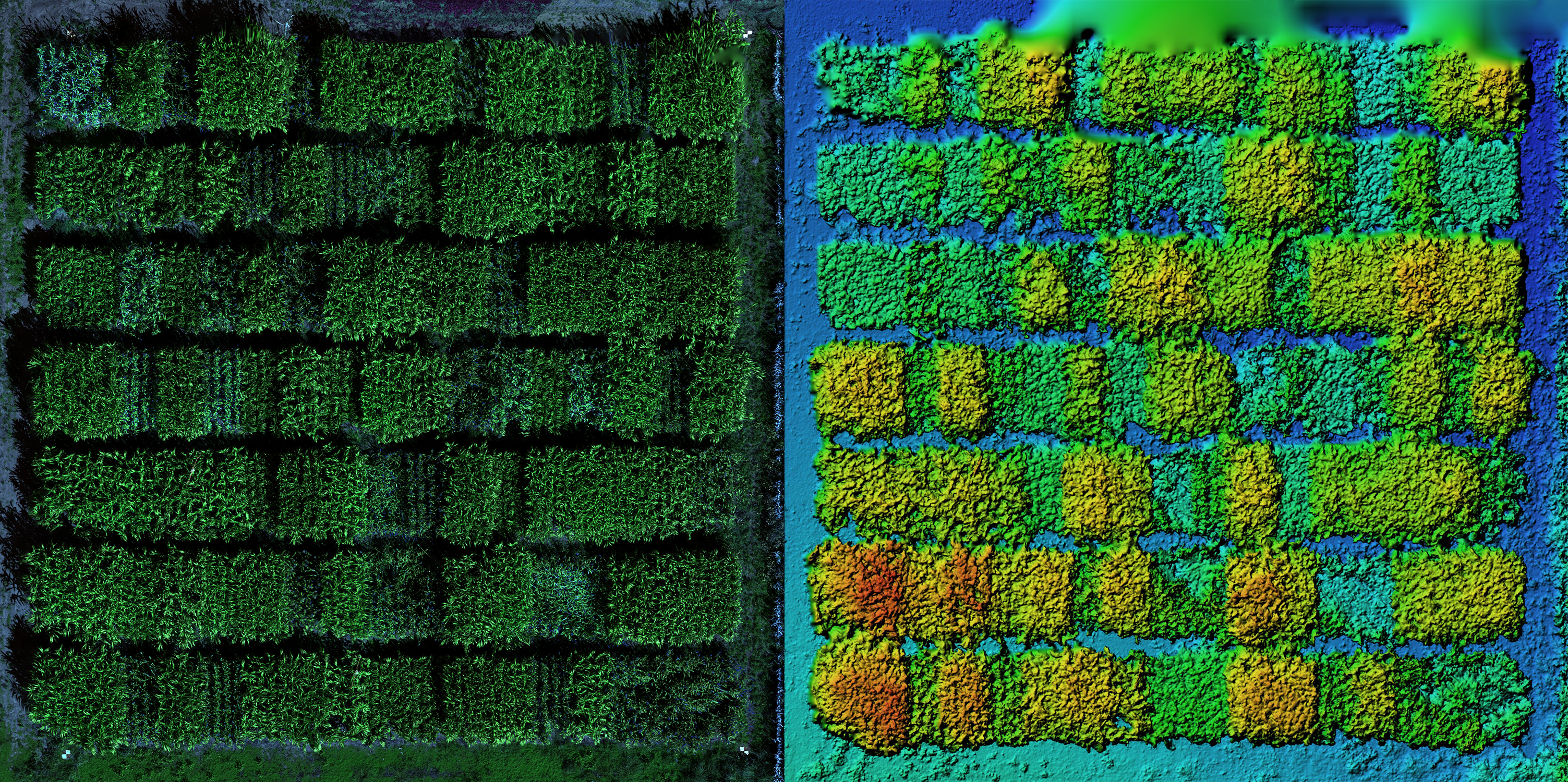

Aerial Drone Imaging

Aerial drone imaging to predict end-season yields, improvements on cellulose extraction procedures, and testing of bio-based sensors in the field or greenhouse are all examples of other projects we are currently collaborating on with other research groups.

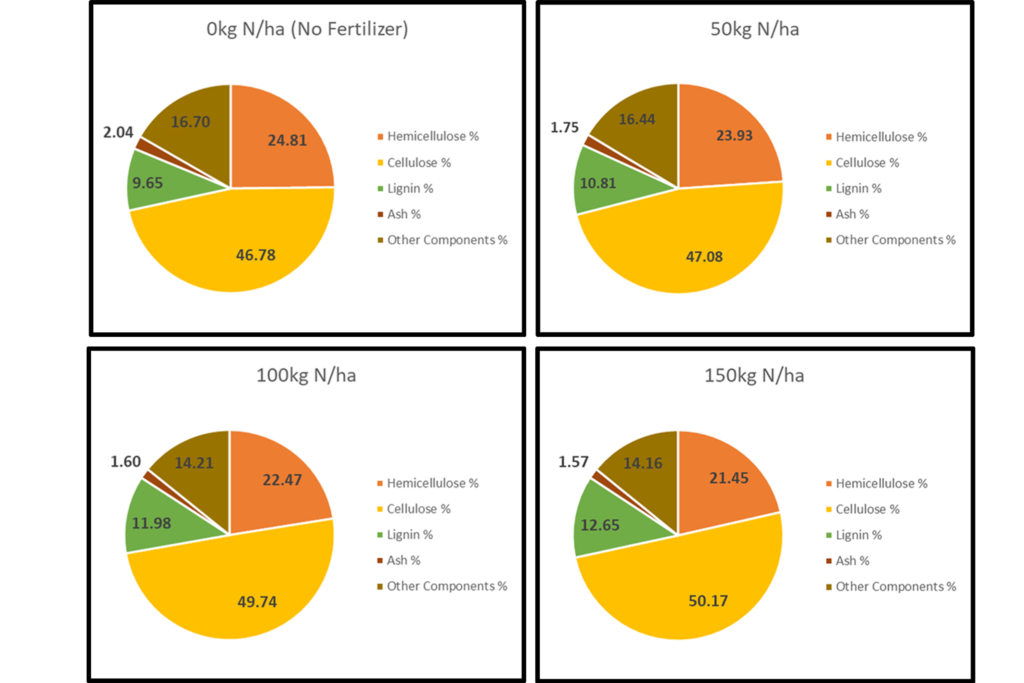

Fiber Analysis

Biomass harvested from the aeroponic systems undergo wet chemistry procedures to quantify the chemical composition of fiber and understand if ratios of cellulose, hemicellulose, lignin, and ash responded to different fertilizer treatments. This involves sequential rinses using neutral detergent solution, acid detergent solution, and diluted sulfuric acid for targeted removal of specific components from the biomass. By measuring sample mass before and after a given solution rinse, we can estimate the percentage contents of our biomass samples. Ash content is estimated by a separate process, where biomass is burned over several hours to remove all components except ash.

Want to Learn More?

Click this image to visit the Future Manufacturing Research Group webpage at MADE-PUBLIC | Eco Manufacturing.

MADE-PUBLIC Project Members

Kayla Vittore

Graduate Student (PhD)